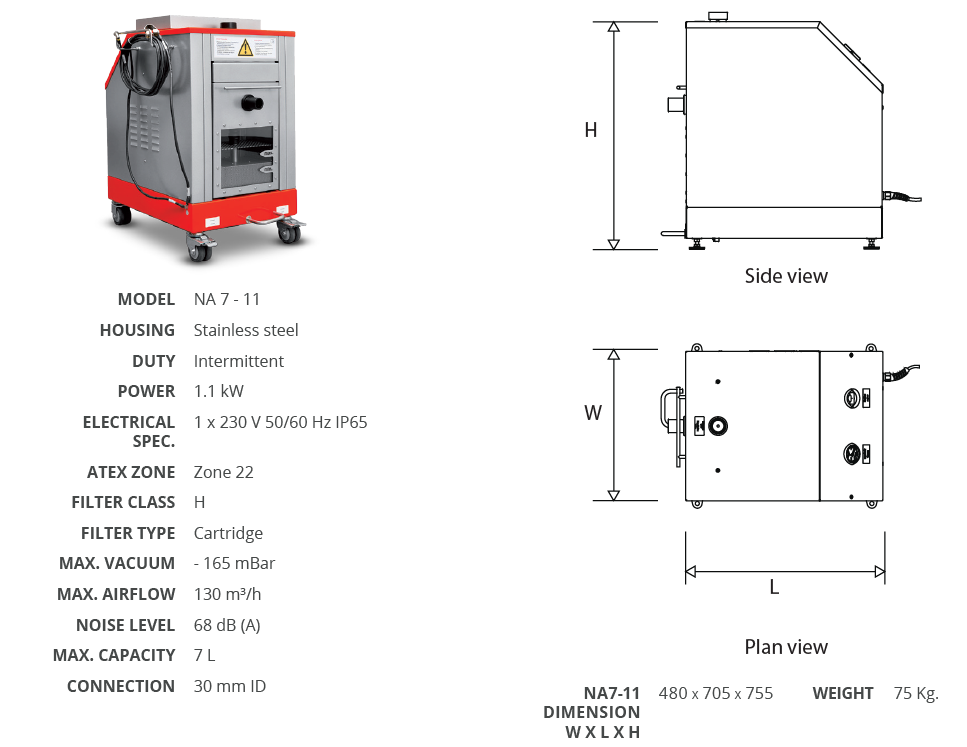

PRODUCT OVERVIEW

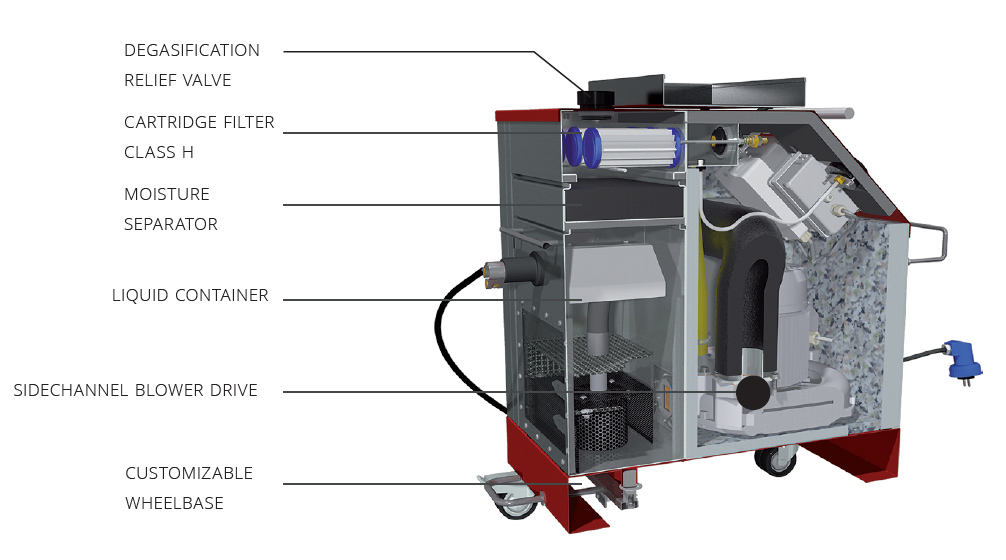

This small Wet Separator vacuums the dust loaded air and guides it into a collecting tank which is filled with liquid. In this collecting tank air, dust and liquid are swirled which lets the dust attach to the liquid. The full collecting tank can be removed easily in order to dispose the sediment.

The RUWAC wet separation vacuums are safe vacuum cleaning machines for highly combustable and reactive powders in Additive Manufacturing such as Titanium, Aluminium and Magnesium.

| Image | Article no. | Description |

| Electrical Customization | ||

|

902658 | Machine execution with all electrical components UL certified |

|

901323 | Electrical System 1.1 kW change to : 1.5 kW 1 * 110 V 60 Hz IP 65 |

|

901324 | Electrical System 1.1 kW change to : 1.5 kW 1 * 120 V 60 Hz IP 65 |

|

901325 | Electrical System 1.1 kW change to : 1.5 kW 1 * 220 V 60 Hz IP 65 |

| Control System Function | ||

|

63232 | Filling level control in NA7-11 (proximity switch) for NA 7 - 11 models |

| Potential Equalization for Reactive Materials | ||

|

59803 | Potential equalization for NA 7-11 wet separator: 6 meter wire W233 H07 RN-F 1X6mm² black with wire termination 6mm² and potential equalization-connector 90° |

| Wheelbase Customization | ||

|

72611 | Wheel with rubber protection equipped on all corners Optional from standard wheelbase |

| Plugs | ||

|

902544 | CEE Plug IP67, 2P+E 16A 230V Blue |

|

902543 | CEE Plug IP67, 2P+E 16A 110V Yellow |

| Option | ||

|

70943 | Trolley for removing and transport of liquid tank for NA 7 |

| Image | Article no. | Description |

|

902560 | Accessory Pack DN 30 mm x 3.0 meter hose for Vacuum cleaning of reactive powders and other suction media's sensitive to static charges. Includes: Conductive (M) PUR Black DN 30 mm * 3.0m Hoses , a diameter 35mm curved hand pipe made of stainless steel, stainless steel crevice nozzle for 35 mm connection, an anti-static brush with a stainless steel body, and a stainless steel suction nozzle with a 15 mm anti-static plastic replaceable cap |

| Image | Article no. | Description |

|

901346 | Complete set of 3 CARTRIDGE FILTER 0.10 m² with dust class H and PTFE coated Recommended change period: 100 operating hours |

|

59120 | Moisture separator size 290x190x50 mm Recommended change period: 100 operating hours |