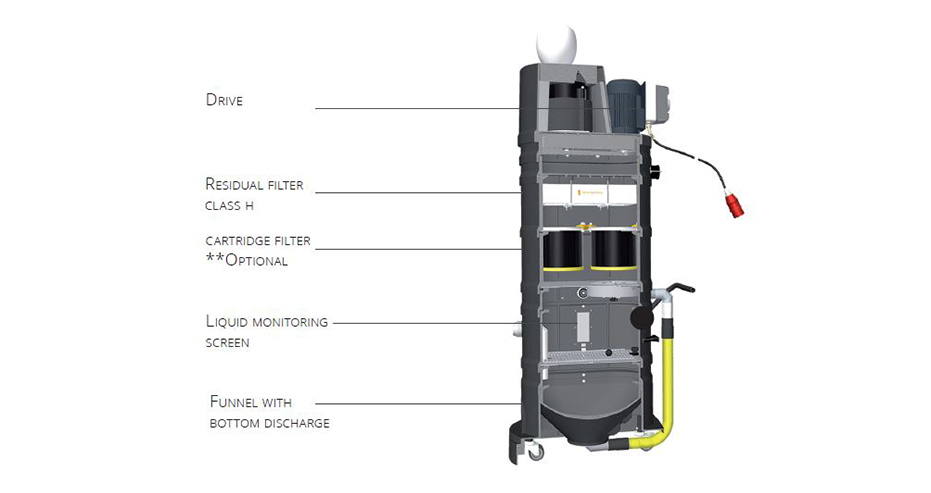

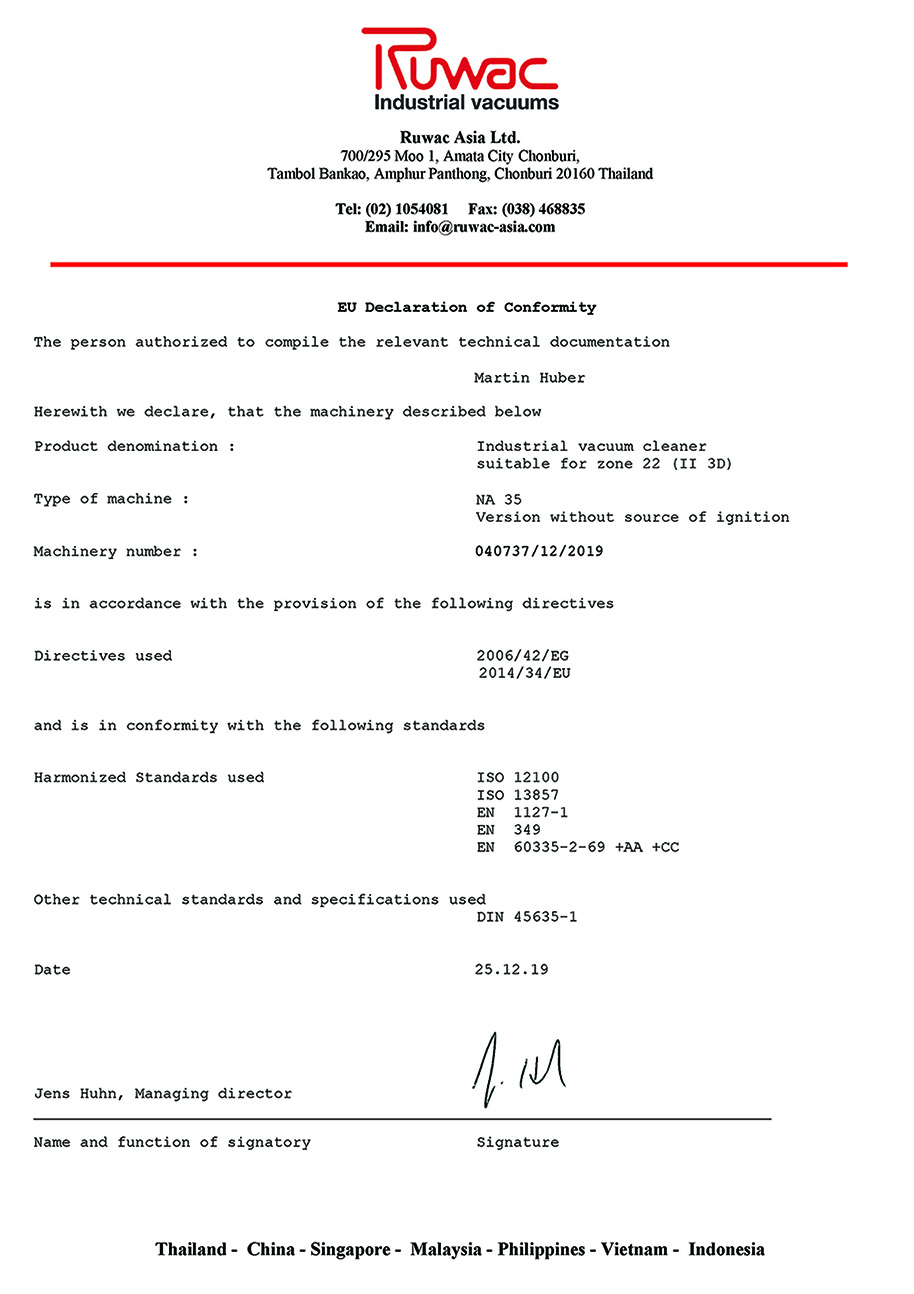

PRODUCT OVERVIEW

Wet separators are used for separating dust and dust particles of all types. The particles are channeled into liquid media, where they are safely trapped. Our wet separators come in various models of different sizes. They are especially suitable for materials such as propellant powder, explosives, titanium, aluminium dust or magnesium dust. The dust is submerged in liquid media, where it is no longer flammable. They can even be used for cooling hot gases.

| Image | Article no. | Description |

| Electrical Customization | ||

|

902658 | Machine execution with all electrical components UL certified |

|

901275 | Electrical System 2.2 kW change to : 3 x 415 V 50 Hz IP 65 |

|

901276 | Electrical System 2.2 kW change to : 3 x 220 V 60 Hz IP 65 |

|

901277 | Electrical System 2.2 kW change to : 3 x 380 V 60 Hz IP 65 |

|

901278 | Electrical System 2.2 kW change to : 3 x 460 V 60 Hz IP 65 |

|

901279 | Electrical System 4.0 kW change to : 3 x 380 V 50 Hz IP 65 |

|

901280 | Electrical System 4.0 kW change to : 3 x 415 V 50 Hz IP 65 |

|

901281 | Electrical System 4.0 kW change to : 3 x 220 V 60 Hz IP 65 |

|

901282 | Electrical System 4.0 kW change to : 3 x 380 V 60 Hz IP 65 |

|

901283 | Electrical System 4.0 kW change to : 3 x 460 V 60 Hz IP 65 |

|

901631 | Electrical System 4.0 kW change to : 3 x 440 V 60 Hz IP 65 |

|

902388 | Electrical System 4.0 kW change to : 3 * 200 V 50 Hz IP 65 |

| Machine Customization | ||

|

45280 | Filling level control with proximity switch for liquids for min level monitoring Installed: at NA35 Sensor: liquiphant, 1"OD thread Fork: 130mm long Electronic: 10...55VDC Protection: IP67 inclusive 1 m. cable, without control unit "APPLICABLE FOR NA35 MACHINE WITH MANUAL START/STOP" |

|

17789 | Level Monitoring/control for wet separator (requires Control system basic or extended) Level monitoring: Min. - Max. Function: Signal or switch OFF Sensor: 2x piece liquid level switch Mount for: NA wet separator Control cable: max. 5.0 meter |

|

901566 | Differential pressure control on the main filter equipped with Indicator lamp and text message "Filter Clogged" |

|

902632 | Potential equalization for NA 35 integrated in control system |

|

71965 | Potential equalization for NA 35 |

|

37156 | M Class filter cartridge module 2 x 1.7 m2 for NA 35 The cartridge filter can be regenerated |

|

12064 | Hose rack mounted on the machine front |

|

34947 | Accessory rack mounted on the side of the machine |

| Add-On Option | ||

|

902488 | Stainless Steel Cyclone DN 250 for 50 mm raw gas inlet with 70 L Preseparator bin in stainless steel on trolley with Tipping mechanism and bag suction |

|

10484 | 3m DN 50mm Hose connection between preseparator and NA 35 |

|

22447 | Extraction arm stainless steel DN 50 mm |

| Image | Article no. | Description |

|

901210 | Accessory Pack No. 16 - DN 35 mm : Vacuum cleaning of reactive powders and other suction media sensitive to static charges. Hose DN40x 3 m conductive PUR wall Art.72650 / Curved hand pipe DN35mm Article 10373 / Crevice Nozzle DN35 Art. No 43690 / Antistatic Brush Art no. 72562 / Suction Nozzle DN35mm suction side DN15mm art. no 72653 / Spare Brush Art. no 72555 |

|

902239 | Accessory Pack No. 17 - DN 35 mm : Vacuum cleaning of reactive powders and other suction media sensitive to static charges. Hose DN40x5.0m art no. 902240 conductive PUR wall Curved handpipne DN35mm Article 10373 Crevice Nozzle DN35 Art. No 43690 Antistatic Brush Art no. 72562 Suction Nozzle DN35mm suction side DN15mm art. no 72653 Spare Brush Art. no 72555 |

| Image | Article no. | Description |

|

46500 | Residual dust filter 3.2m² |

|

20712 | Cartridge filter 1.7m² For model equipped with the optional cartridge filter module |

|

25124 | Demister mat OD 260mm x 50mm made of stainless steel |

|

13083 | Air outlet bag exhaust diffuser |

|

16008 | Worm drive clamps 60-80mm |