Solution Overview

Ruwac solutions for metalworking industries

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, and assemblies. Such metalworking methods are in an industry such as foundry, steel industry, engineering, and automotive parts.

These factories use grinders, drills, tapers, and mills to reshape their metals.

And some of these processes need to use liquid coolant or oil to cool down the tools, and this process leaves residuals of metal chips in the liquid.

This mixture is difficult to take out. Some metals, if mixed with liquid, can be reactive and dangerous. And it needs to be carefully handled.

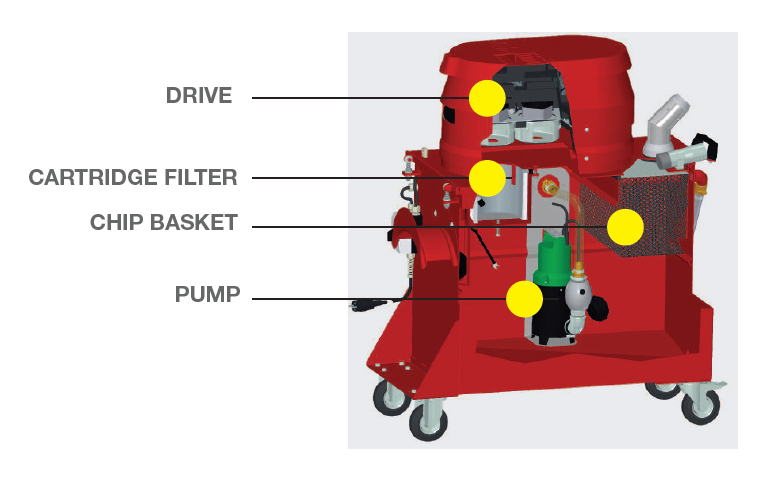

Our RUWAC SPS metal chips separator vacuum can help you safely clean the residue of the product. Our equipment can be optionally customized with liquid pump to continuously drain the liquid out. Machines are available for General Zone and ATEX Zone 22 applications.

metalworking industries SPS metal chips separator vacuum liquid coolant grinders, drills, tapers, and mills to reshape metalworking industries SPS metal chips separator vacuum liquid coolant grinders, drills, tapers, and mills to reshape metalworking industries SPS metal chips separator vacuum liquid coolant grinders, drills, tapers, and mills to reshape